Clinac Downtime

How is "downtime" defined for our linacs?

- Downtime is the time when the machine cannot be operated during normal operating hours.

- Normal operating hours: weekdays, 7 a.m. - 5 p.m. (10 hrs).

- The days of preventive maintenance inspections (PMI) do not count as downtime. Each machine is allowed to be down for 8 days per year (4 PMIs per year, 2 days per PMI).

- We do not distinguish between the machine being down during patient treatments or during quality assurance. Physics QA is done during normal operating hours. In both cases, if the machine cannot be operated, downtime is recorded.

- The clock starts ticking as soon as the machine is down, but we do not record short interruptions (<10 min).

The operating hours per year are calculated by taking the daily working hours (10) and multiplying them with the operating days per year. Example: in 2004, there were 245 operating days: 366 (total) - 52*2 (weekends) - 9 (national holidays during the week) - 8 (PMI) = 245 operating days. This gives 2450 operating hours in 2004.

Downtime Summary (graphics)

| Operating ... | Downtime Clinac Blue1 (details) | Downtime Clinac Green1 (details) | ||||||

|---|---|---|---|---|---|---|---|---|

| Year | ... Days | ... Hrs | Hrs | Percent | Excess | Hrs | Percent | Excess |

| 1997 | 243 | 2430 | 18.0 | 0.7 | 59.0 | 2.4 |  2 2 |

|

| 1998 | 243 | 2430 | 21.75 | 0.9 | 36.5 | 1.5 | ||

| 1999 | 244 | 2440 | 7.5 | 0.3 | 128.83 | 5.3 |  |

|

| 2000 | 240 | 2400 | 161.75 | 6.7 |  |

16.5 | 0.7 | |

| 2001 | 242 | 2420 | 33.5 | 1.4 | 49.75 | 2.1 |  |

|

| 2002 | 243 | 2430 | 59.0 | 2.4 |  |

38.5 | 1.6 | |

| 2003 | 242 | 2420 | 6.83 | 0.3 | 21.5 | 0.9 | ||

| 2004 | 245 | 2450 | 40.5 | 1.7 | 15.16 | 0.6 | ||

| 2005 | 242 | 2420 | 47.0 | 1.9 | 17.91 | 0.7 | ||

| 2006 | 240 | 2400 | 62.0 | 2.6 |  |

64.25 | 2.7 |  |

| 2007 | 241 | 2410 | 46.25 | 1.9 | 38.5 | 1.6 | ||

| 2008 | 245 | 2450 | 63.25 | 2.6 |  |

42.75 | 1.7 | |

| 2009 | 242 | 2420 | 47.0 | 1.9 | 28.66 | 1.2 | ||

| 2010 | 244 | 2440 | 42.42 | 1.7 | 45.25 | 1.9 | ||

| 2011 | 242 | 2420 | 63.58 | 2.6 |  |

15.58 | 0.6 | |

| 2012 | 242 | 2420 | 15.333 | 0.6 | 14.34 | 0.6 | ||

| 2013 | - | - | 11.754 | |||||

1: Blue = Clinac 2300C/D (S/N 157), Green = Clinac 2300C/D (S/N 156).

2: A red triangle indicates that the downtime exceeds 2%.

3: Last treatment day on linac Blue was April 13, 2012 with 3060 lifetime-beam hours after 16 years of operation (June 1996 - April 2012). See the last pictures of this machine.

4: The Clinac era of our institute ended with the last treatment day on linac Green on February 28, 2013 after nearly 17 years of operation. Here is a photo of the physics team in front of the machine (it had 3260.3 beam hours and 54485.5 filament hours).

Modulator Troubleshooting 1999/2000

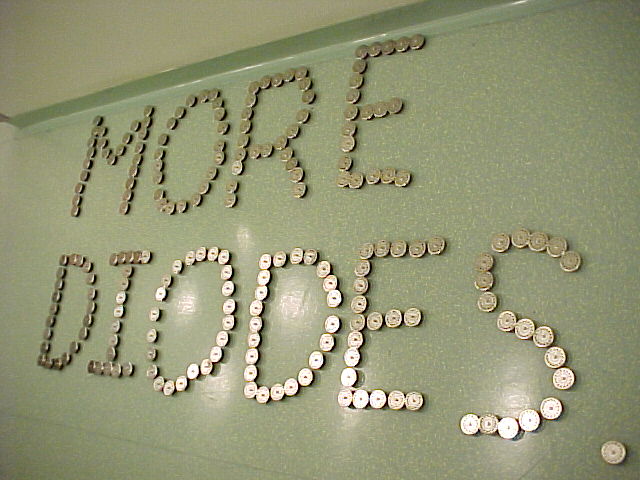

In 1999 and 2000, a lot of downtime was accumulated by troubleshooting modulator problems. The symptoms were always the same: upon beam-on, first there was no output. After a few seconds, a bang from the modulator was heard. This told us that the rectifying diodes in the modulator had blown and required replacement. The deeper reason was the arrangement of some high voltage components inside the modulator, which led to arcing under certain conditions. After extensive troubleshooting, replacing a significant number of diodes and increasing the distance between some HV parts by a few centimeters, we fortunately never had this kind of problem again.

|

|

|

|

Description of Some Interlocks

| ACC | Accessory selected at the console does not match the mounted accessory |

| BMAG | Bend magnet power supply voltage 5% off set value or bend magnet current 1% off for the selected energy |

| CARR | Carrousel not in correct position for selected mode |

| COLL | Collimator. Incorrect position for accessory or mistracking during dynamic wedge treatment |

| ENSW | Energy switch not in correct position for selected mode |

| FLOW | Insufficient water flow opened a flow switch |

| FOIL | Carrousel locking pin not in home position |

| GAS | SF6 waveguide gas pressure less than 30 psi |

| GFIL | Gun filament and bias voltages below proper operating level for accelerator gun |

| HVCB | High voltage circuit breaker |

| HVOC | High voltage overcurrent |

| HWFA | Hardware failure |

| ION1 | Radial ion chamber power supply less than 400V |

| ION2 | Transverse ion chamber power supply less than 400V |

| KSOL | Klystron solenoid current not within 1.5 amps of the name-plate rating or power supply voltage 10% below nominal |

| PNDT | Hand pendant not in holder or treatment couch brakes not engaged |

| STPS | Steering motor power supply |

| TARG | Target not in correct position for selected mode |

| UDR1 | Radial dose rate less than 80% of set value (disabled for the first 10s after beam-on) |

| UDR2 | Transverse dose rate less than 80% of set value (disabled for the first 10s after beam-on) |

| UDRS | Actual servoed dose rate below that which was intended |

| VAC1 | Major leak, defective Vacion power supply, ... |

| VAC2 | Momentary, self-clearing impurity, minor leak, defective Vacion power supply, ... |