The Modular Rotation Unit

The Control Unit (T40058) drives the Rotation Unit (T40063) based on the Inclinometer information.

The following video shows the accuracy with which the Rotation Unit follows the gantry. Field size is set to 10 x 10 cm. Since the TrueBeam field light is turned on during the manual rotation, one can see where the beam central axis is:

There seems to be some hysteresis in the movement. It is obvious that the Control Unit cannot know what will happen next, so it is always a little behind. At rapid changes of direction or velocity, the phantom therefore lags behind a little.

However, the discrepancy (cross-hairs on the phantom versus light field cross-hairs) is visible only at the surface of the phantom (radius: 16 cm), not in the plane of measurement. The small angle error in the center of the phantom is probably negligible.

The SRS Top

With the OCTAVIUS Top SRS installed (radius: 8.5 cm), the effect is smaller, because the surface is closer to the rotation axis:

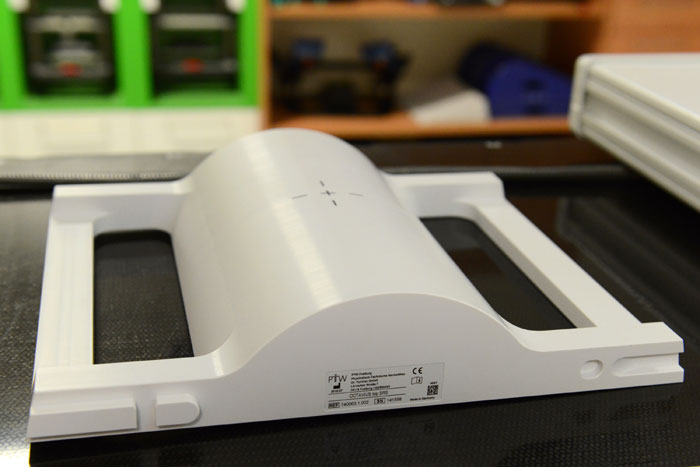

Here is a picture of the SRS top alone:

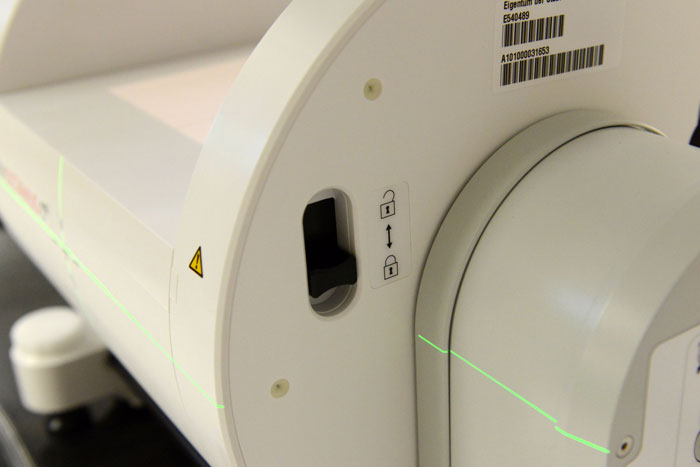

The red arrow points to the locking pin which has to be pulled out on the back side of the Rotation Unit to release the tops:

The locking pin does not stabilize the top laterally. The top still has some play. It is a mere security mechanism which keeps the top from falling out during rotation.

Full stability is reached by engaging another lock on the back side:

Moving the slider down removes practically all of the mechanical play the top might still have. The modular Rotation Unit is then rigid during rotation just like the older non-modular unit was.

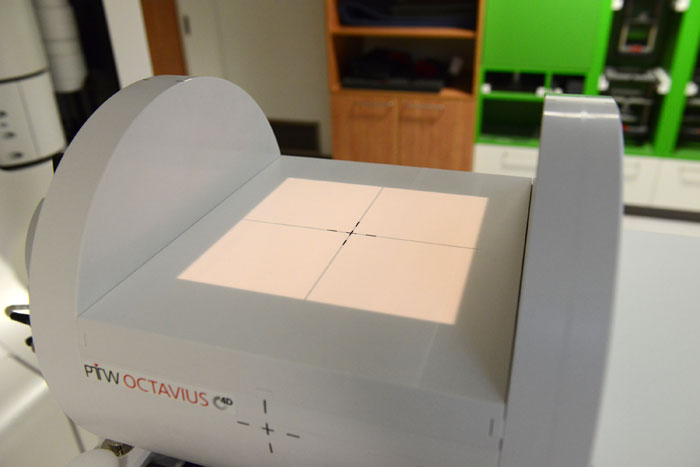

The Top for Linac QA

The top for Linac QA provides a constant 5 cm buildup over the whole measurement plane. For the photo, the field size has been changed to 20 x 20 cm (more appropriate for linac QA):